How to Thread a Sewing Machine: A Complete Guide

Learn how to thread a sewing machine with a clear, step-by-step guide, practical model tips, and essential safety reminders for beginners.

Threading a sewing machine correctly is the first step toward consistent stitches and fewer jams. This guide covers the standard upper thread path, the take-up lever, and bobbin threading, plus model-specific tips. According to Sewing Machine Help, proper threading reduces tension problems and thread nests. By following the steps below, you’ll thread with confidence on most domestic machines.

Why Threading Matters

Threading a sewing machine correctly is the foundation of good stitching. According to Sewing Machine Help, proper threading reduces skipped stitches, thread breaks, and fabric jams. The Sewing Machine Help team found that when both upper and bobbin threads are correctly engaged, tension stays balanced and fabric feeds smoothly. In this article, you’ll learn the exact steps and fallbacks for common models, plus troubleshooting tips for stubborn threads. Proper threading also makes free-motion or decorative stitching more predictable, which is especially helpful for beginners and hobbyists who are developing their technique.

Core Threading Concepts

Almost every sewing machine shares the same threading principles: the upper thread travels from the spool through a sequence of guides, down to the take-up lever, through tension discs, and toward the needle. The bobbin thread sits in its own case and must be positioned to feed upward at the right moment. The goal is to have the two threads meet beneath the fabric so stitches are formed cleanly. No matter the model, a clean thread path reduces friction, prevents lint buildup, and minimizes the chance of thread bunching.

Model Variations You Might Encounter

Domestic mechanical machines, computerized models, and vintage hand-crank units all require threading, but the exact path can vary. Some have extra guides or a different take-up mechanism, while others use a drop-in bobbin with a transparent cover. When you’re unsure, consult the user manual for your machine’s specific threading sequence. The core principles stay the same: secure upper thread, proper take-up alignment, and correct bobbin orientation. With practice, you’ll recognize your model’s quirks and thread reliably.

Common Pathways Across Most Machines

While there are exceptions, most machines share a familiar threading route: start at the spool, pass through the thread guide on the head, loop through the thread path down to the needle bar, through the take-up lever, and then reach the needle. The bobbin typically threads in a separate path, either clockwise or counterclockwise, and the bobbin thread must be brought up through the needle plate before you begin stitching. Keeping the path smooth and tension balanced is the key.

Step-by-step Overview (High-level)

This overview aligns with the more detailed STEP-BY-STEP section. First, prepare your thread and needle. Then place the spool on the pin and guide the thread through all upper-thread guides, ending at the needle. Next, thread the bobbin in its case and place it properly. Finally, pull both threads to ensure they pull smoothly from the needle and bobbin when you test stitch on scrap fabric.

Leftover Mistakes to Avoid

Common threading mistakes include skipping a guide, not seating the thread fully in a guide, or forgetting to pull the thread significantly to engage the take-up lever. A loose needle or incorrectly inserted needle can also disrupt threading. Take your time, especially when using a new spool or a different type of thread. Regularly check for lint around tension discs, as lint can alter tension and undermine the threading process.

How to Diagnose Tension Issues During Threading

If your stitches are uneven or your thread nests form under the fabric, recheck the upper thread path and bobbin installation. Ensure the take-up lever moves freely and that the thread sits correctly in each guide. Change to a fresh needle if the needle eye is bent or the needle is dull, as a dull needle can crush the thread at the point of contact. A clean bobbin case and smooth tension discs are essential for balanced stitching.

Model-Specific Tips: Brand Variations You Might Encounter

Some brands place the take-up lever directly above the needle, while others route through additional guides. For example, a few Bernina and Brother models require a particular angle for the bobbin thread to feed correctly. Always align the needle so it sits straight and not at an angle when threading, and keep the area around the bobbin housing clean to avoid jams. If in doubt, a quick check of your machine’s manual can spare you hours of frustration.

Quick Reference: Common Signs of Incorrect Threading

Look for skipped stitches, frequent thread breaks, or thread nests beneath the fabric. If you see lint in the tension discs or hear a grinding sound when pulling the thread, stop and re-check the path. Misalignment of the take-up lever is a frequent culprit, as is a bobbin that isn’t rotating the right way or sitting loose in its case. Correct threading should feel smooth when you pull both threads away from the needle.

Maintenance After Threading

After you thread and test your stitches, take a moment to clean the bobbin area and dust off lint from the feed dogs. Regular lubrication (as directed by your model’s manual) helps long-term performance. Keep spare needles on hand and replace them if they become bent or dull, as a sharp needle reduces the chance of snags during threading and stitching. Periodic checks also reduce the frequency of threading-related interruptions during projects.

Tools & Materials

- Spool of sewing machine thread(Polyester or cotton blend works well for most projects)

- Bobbin (empty)(Pre-wound or wound onto the bobbin as needed)

- Needle (proper size for fabric)(Common sizes: 80/12 or 90/14 for woven fabrics)

- Scissors or thread snips(Sharp, small scissors for clean cuts)

- Needle threader (optional)(Helpful for tiny needle eyes)

- Manual or guide for your machine(Useful for model-specific steps)

- Lint brush or small brush(Keeps tension discs clean)

- Good lighting(Essential for threading carefully)

Steps

Estimated time: 15-25 minutes

- 1

Prepare thread and needle

Select the correct thread and needle for your fabric. Inspect the needle for burrs or bending. Threading starts best with a clean, wrinkle-free fabric area and a properly installed needle.

Tip: If the needle is new, verify it’s the right type for your fabric to prevent snagging. - 2

Place the spool and secure thread

Position the spool on the pin and secure it with the thread cap or stopper. Leave enough thread to reach the first path guide. Ensure the spool isn’t loose and the thread unwinds smoothly.

Tip: Use a spool cap to prevent thread from slipping off the spool during threading. - 3

Guide the upper thread through guides

Follow the machine’s upper thread path from the spool toward the take-up lever, passing through all guides in order. Do not skip guides, and ensure the thread sits in each guide securely.

Tip: If your machine has multiple guides, take a moment to confirm the correct sequence with the manual. - 4

Thread the take-up lever

Bring the thread to the take-up lever and thread it through from back to front. The lever should move freely when you gently pull the thread.

Tip: If the take-up lever is stiff, consult the manual; forcing the thread can bend the mechanism. - 5

Thread the needle

Lower the presser foot, hold the thread taut, and guide it through the needle eye. If the needle is difficult to thread, use a needle threader or a magnifier.

Tip: Threading the eye with the fabric still in place reduces the chance of bending the needle. - 6

Wind and thread the bobbin

Wind the bobbin evenly and place it in its case according to your model’s direction. Ensure you understand whether the bobbin rotates clockwise or counterclockwise as you thread.

Tip: Use a clear bobbin case if possible to verify thread flow. - 7

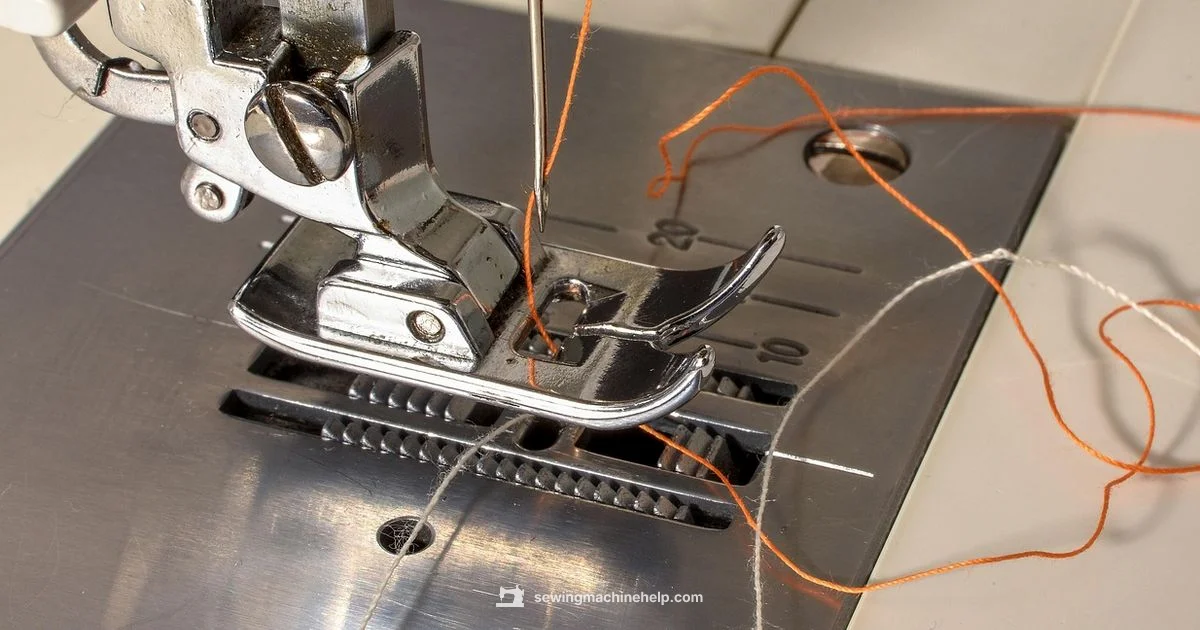

Position bobbin thread and bring it up

Hold the upper thread with your left hand and gently turn the handwheel toward you to catch the bobbin thread. Pull both threads toward the back to clear the area before stitching.

Tip: If you don’t see the bobbin thread come up, re-check the bobbin path and ensure the needle is threaded correctly. - 8

Test the stitch on scrap fabric

Lower the presser foot, hold both threads, and sew a few stitches on scrap fabric. Check tension and ensure both threads pull evenly from the needle and bobbin.

Tip: If stitches skip or nest, re-check the path and adjust the tension discs if needed (per manual). - 9

Finalize and clean up

Trim excess threads, remove lint near the bobbin area, and re-test. Store tools in a handy location and keep your manual accessible.

Tip: Keep a small spool of extra thread on hand for quick repairs. - 10

Troubleshoot common issues

If you encounter persistent problems, revisit each stage of threading, inspect for bent needles, and verify the fabric type aligns with the chosen needle and thread.

Tip: Document the steps that work best for your model for future reference.

Your Questions Answered

Do all sewing machines thread the same way?

Most machines share a common threading path, but exact guides and the bobbin mechanism can vary by brand and model. Always consult your manual for model-specific steps.

Yes, many machines share the same basics, but check your model’s manual for exact steps.

Is it okay to thread without removing the needle?

Threading with the needle in place is possible on many machines, but for some models you must lower the presser foot and thread through the guides with the needle raised. Check your manual for your model.

Often you can thread with the needle in place, but some machines require a specific order.

What is the correct order to thread a bobbin and machine?

Typically, you thread the upper path first, then thread the bobbin separately, and finally bring the bobbin thread up through the needle plate. The exact order can vary by machine, so verify with your manual.

Thread the upper path first, then the bobbin, and bring up the bobbin thread through the needle plate.

Why is my thread breaking during threading?

Thread breaks usually indicate a sharp needle, an incorrect needle type for the fabric, or a rough thread path. Replace the needle and re-thread carefully, ensuring the thread sits properly in each guide.

Thread breaks often mean a dull needle or a rough threading path—check the guides and replace the needle.

How can I fix thread nests under the fabric?

Thread nests are often caused by tension imbalance or an incorrectly threaded bobbin. Re-thread both the upper thread and bobbin, verify the take-up lever moves freely, and test on scrap fabric.

Nests usually come from tension issues—re-thread both paths and test on scrap.

What should I do if the take-up lever won’t move?

A stiff take-up lever can be caused by lint or a mis-threaded path. Clean the area, re-thread in the correct sequence, and ensure the lever can move smoothly when the machine is off.

If the take-up lever is stiff, clean the area and re-thread in order.

Watch Video

The Essentials

- Master the upper thread path for consistent stitches

- Always position and test the bobbin thread before sewing

- Use scrap fabric to verify tension and threading sequence

- Keep your machine clean and well-lubricated as per the manual